What is Micro Soldering: Explained

If you’re a professional in electronics, connector manufacturing, repair services, or you distribute components for such industries, you’ve very likely heard this term: micro soldering. But let’s get honest and transparent about what that means, why it matters, and how it differs from “ordinary” soldering. I’m speaking as someone who deals with fine-pitch assemblies and precision wiring—so yes, I’ve been where you are: wondering if the technique really is worth the effort.

Getting to the core: the definition

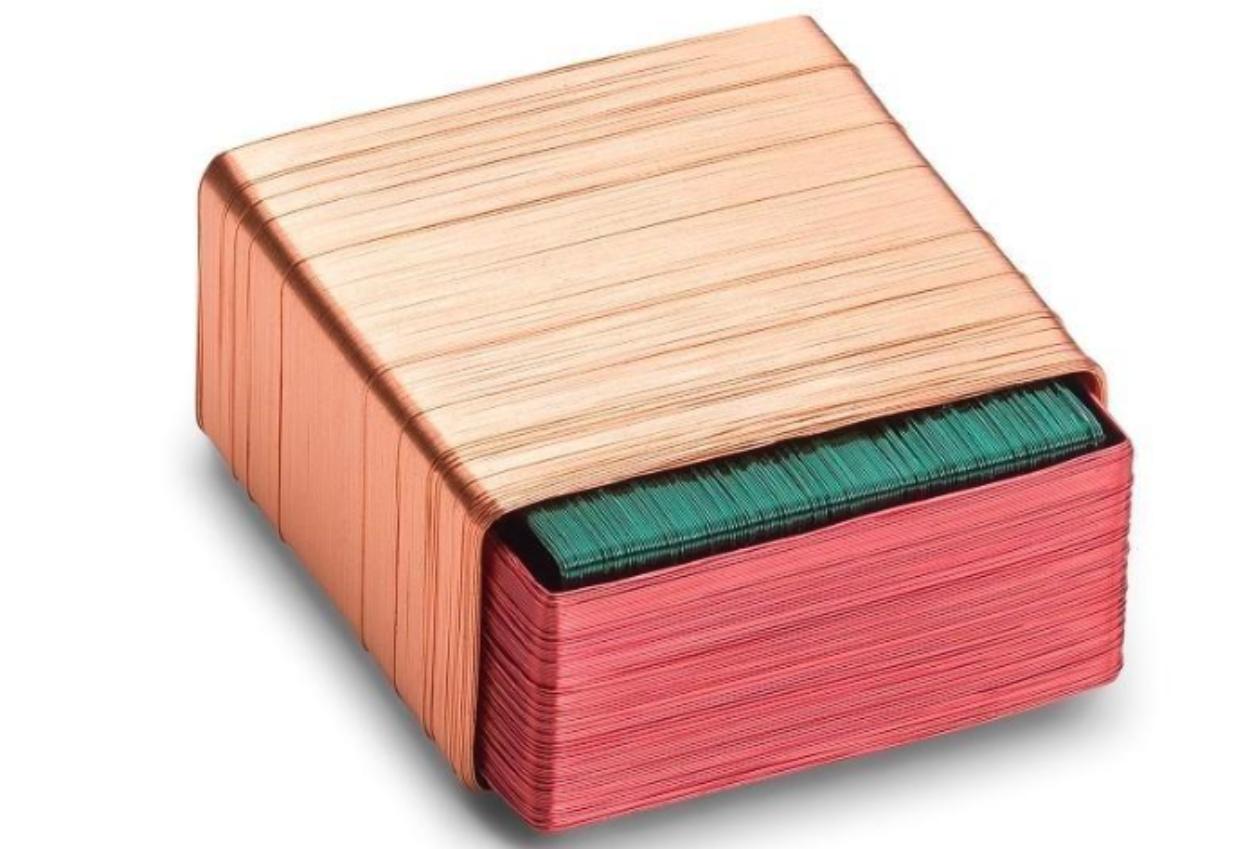

In simple terms, micro soldering is the process of joining ultra-fine wires or tiny components, often in areas where traditional soldering or welding cannot be used. According to one source, this can mean joining wires as thin as 9 microns (which is roughly 5-10 times smaller than a human hair).

What pops out right away is: when your wires/components are that small, the usual tools and methods won’t cut it. Heat spreads differently, materials behave differently, and tolerances are razor-thin. That’s why micro‐soldering is distinct.

Why it’s not just “small soldering”

Suppose you used a regular soldering iron to attach a 9-micron wire to a board. In that case, you’d likely cause damage, including heat burns, oxidation, stray flows, and mechanical strain, which could potentially result in the tiny wire detaching later. Traditional methods fail because:

- Heat spreads too widely and kills the surrounding cables.

- Oxidation and physical strain reduce reliability.

- Access is constrained; the process demands higher precision.

In other words, micro soldering isn’t just doing the same thing on a smaller scale; it’s a different technique, with different tooling, controls, and expectations.

Key attributes and applications

So what are the main features of micro soldering that you need to understand (especially if you buy, specify, or repair these systems)?

- Ultra‐fine conductor sizes: As noted above, wires down to 9 µm diameter.

- Exact joints: Since components are small, the joint must be precise and clean.

- High reliability under constraints: Many micro-soldered assemblies are used in critical environments (medical implants, sensors, micro-motion systems) where failure is not an option.

- Specialized equipment Includes Microscope magnification, fine soldering tips, and controlled heat/air flow systems. According to a repair-industry perspective, microsoldering utilizes a microscope, fine-tipped tools, and precise thermal control.

And the applications? They range from ultra-miniature medical implants and sensors to high-density, board-level repairs in electronics.

For you – why this matters in your world

If you are specifying parts, dealing with contract manufacturing, repair services, or you’re a designer/distributor of mini-electronics, here are the reasons micro soldering deserves your attention:

- Quality and reliability: When wires or components are ultra-fine (as they often are in today’s devices), using the proper micro soldering process means fewer failures, higher yields, and less re-work.

- Cost control: Yes, the equipment and control cost can be higher, but if you avoid the hidden cost of failures, recalls, or replacements, micro soldering can pay off.

- Competitive edge: Being able to specify or repair assemblies using micro soldering means you can handle more advanced products (wearables, medical implants, IoT sensors), which often demand this level of precision.

- Repair & Service Advantage: For repair shops or aftermarket services, knowing micro soldering means you can fix things that traditional methods won’t handle. That’s a value add.

What to watch for – pitfalls and questions

As you evaluate whether a micro soldering process or service is proper for you, these are things I always bring up:

- What is the minimum wire size or component dimension they can reliably handle? If you think you’ll only ever need “small wires,” but the process can go down to 9 µm, you may be investing wisely.

- What tooling/control do they use? Microscope, fine tip, nature of heat/air control, board handling?

- What is their capability in handling strain, thermal cycling, and reliability over time? If the joints are fine today but fail after a few cycles, you’ll have issues.

- Cost vs yield: Micro soldering may be more expensive per joint than conventional methods—but the yield improvement might be worth it.

- Application fit: Are your assemblies truly requiring micro-level work, or could they be handled with standard soldering? Sometimes, simpler is better if your device tolerances are larger.

Final Summary

If you’re working on next-gen electronics, miniaturized assemblies, medical devices, or high-reliability systems, treat micro soldering not as an optional step, but as a necessary capability. If you’re in repair/aftermarket and face board-level or component-level damage where parts are tiny, invest in understanding this process (or partner with someone who has it). If you’re specifying parts or assemblies, ask: “Are you using micro‐soldering, or is this just standard soldering scaled down?” That question will distinguish between “good enough” and “optimized for the job”.

FAQs

Can micro soldering replace standard soldering for all applications?

Not necessarily. If your project utilizes larger components, standard soldering is more cost-effective. Micro soldering is most beneficial when dealing with ultra-fine wires, tiny components, or strict reliability demands.

Is special training required for micro soldering?

Yes. The precision, equipment, thermal control, and material behaviour differ significantly from standard soldering. Techniques such as working under a microscope, managing thermal diffusion, and avoiding damage to nearby components are critical.

How can I tell if a micro soldering process is reliable?

Look for evidence: ability to handle ultra-fine wire sizes, consistent yield data, reliability testing (thermal cycling, strain tests), and quality of joints under microscopy. Also, check if the process is used in critical applications (such as medical or aerospace), which often indicates higher reliability.